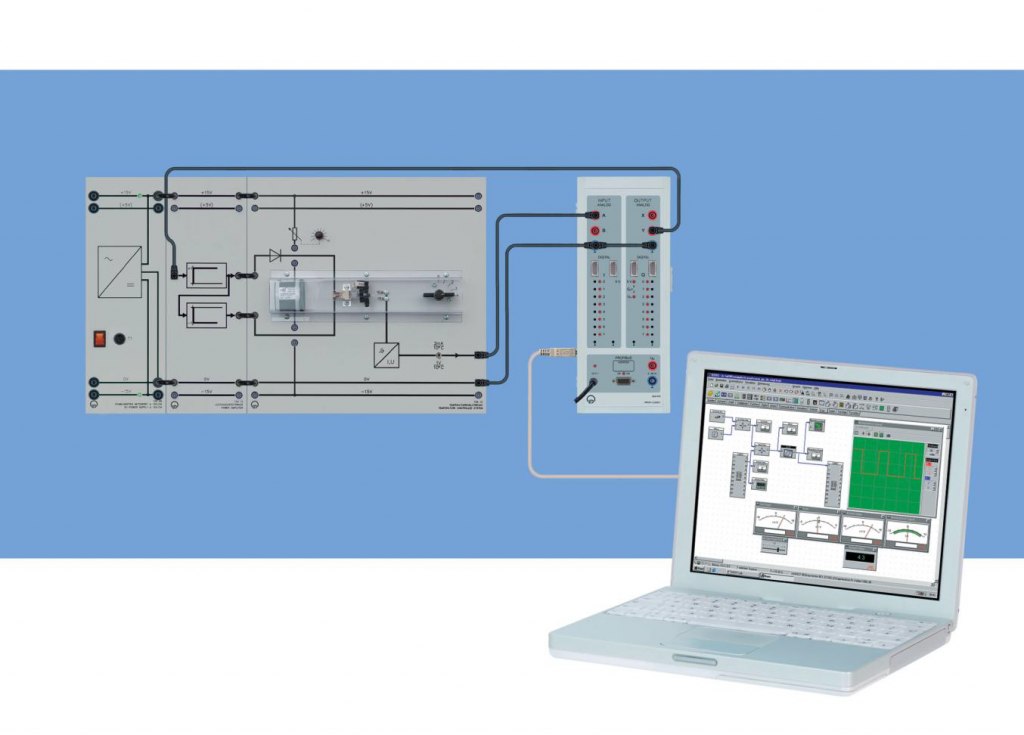

Comprises an experiment board, housed within a board carrier, for use in conjunction with, and powered by the Master Unit (supplied separately) teaching a practical course on the fundamentals of automatic control technology, experiments being wired using 2 mm safety cables (supplied separately). Course content, experiment instructions and tasks are taught via course-specific software.

Curriculum Coverage

- Introduction

- Open-loop control

- Closed-loop control

- Analysis of controlled systems

- Controlled systems with/without compensation

- Controlled systems of a higher order

- Types of controllers

- P, I, PI, PID & PD control

- Automatic digital control

- Performance criteria for automatic controls

- Optimisation guidelines for PID controllers

- Automatic temperature control

- Automatic speed control

- Automatic light control

- Liquid Flow – Measurement and Control

- Liquid Level- Measurement and Control

- Gas Flow Control

- Intensity Control

- Automatic control of systems without compensation

- Automatic control with discontinuous controllers

- Fault simulation

(using Leybold Didactic Laboratory Equipments)

CTR 01- Temperature Control

For the investigation of continuous and discontinuous control loops.

Unipolar heat source (max. 20 W for 20 V) with temperature sensor, thermal protection switch, fan motor and “throttle flap”, built into a transparent air channel. With two integrated power amplifiers for heater and fan, thus ideal for control systems with multi input control (Fuzzy). Three digit 7-segment display for temperature in °C including trend indicator for the temperature change (rising or descending). Two possibilities for controlled system disturbance:

- via fan motor, internally with speed setter 1…10 or from an external signal source max. 20 V

- via “throttle flap”, position 0 (closed) up to position 4 (open)

CTR 02- Liquid Flow – Measurement and Control

As is the case in petrochemistry or water management, level and

flow are integral to motor vehicle technology and fundamental to

production and logistics within industrial applications. Fluid

throughput should be recorded, controlled and corrected at every

stage: from tankers, through refineries, up through the clarification

plant.

CTR 3 – Liquid Level – Measurement and Control

In addition to pressure measurement, temperature, flow, and the

acquisition of filling levels in tanks and containers play a key role

in the chemical industry. Different methods are used to measure

filling levels. The LD training system uses the following probes:

-Capacitive

-Immersion pipe with differential pressure sensor

-Level switch with float

CTR-04: Gas flow control

In classical control circuits, gas flow is measured and maintained at the desired value. The anemometer operates using thermal cross or thermosensors. Applications for gas flow controls include:

-Aeronautics

-Motor vehicles

-Air conditioning

The exploitation of wind energy creates a greater demand for technology which measures and controls flowing gasses. Varying wind speeds should be registered and converted into an optimum blade adjustment for the propeller (pitch control). If maximum energy production is to be achieved, the nacelle must be turned into the wind at all times.

CTR-05 : Intensity control

For the investigation of a fast technical controlled system. PWM modulated light source with a phototransistor as opto-receiver. Analysis of disturbance reaction by means of internally and externally controlled auxiliary light. Additional disturbance control by means of an external light source via a window.

CTR-06 : Speed and Voltage control

The set of machines 10 W is a technical controlled system for

experiments on speed and voltage control. It consists of an

electrical drive including digital speed sensing, a generator

machine and an electronic load. Using the adjustable load, real

generator operation can be investigated. The machine set makes it

possible to measure the load characteristic of the generator and

the dynamic behaviour of systems of higher order. A

microprocessor controlled power module supplies the drive

machine. Thus no external power amplifier is required. The set of

machines comes with 7-segment displays for the measurement of

speed and torque.

CTR-07: Listing control

Listing, or heeling, is the term given to the rolling movement of

ships in waves or during the loading procedure. Listing occurs

particularly when a heavy freight train mounts a ferry. When rail

vehicles mount a ferry, there should be no rail kinks at the

interface between ferry and feeder. Such control problems – all of

which pertain to attitude stabilisation – can be investigated using

listing controls. The system can be similarly operated using the

real PID Digital Controller (734 064) or with a software controller

based on WinFACT.

[embedyt] https://www.youtube.com/watch?v=jVPVhFxC_tg[/embedyt]